SC7USB PQA Definition Guide

NOTE: This is the PQA Definition Guide for the SC7USB 2D Scanner, which is discontinued. This information is kept online to support existing customers only.

Average Bar or InterBar Gap Widths are the average of widths measured across the entire postal barcode. A low score for the average bar width or interbar gap width grade indicates that print conditions either expanded or shrunk the apparent size of the dark portions, thereby threatening to make the narrow bars or spaces disappear.

- Potential areas of correction include adjusting the print process, such as ink flow, transfer heat, and print speed; adjusting the original barcode symbol, or making the symbol larger.

Average Height or Extension Height is a measure of the average height of the bars or the dark portions in a symbol.

- Depending on the symbology and print process, this can be corrected by graphically stretching the symbol for 2D stacked symbols, or it may be an indication that the symbol-generating program, in the case of postal barcodes, did not meet the required specifications.

Bar Sequence is the bar height pattern within a height-modulated, multi-state postal barcode.

- In a 2-State symbol, a "1" represents a tall or full-height bar, and a "0" represents a short or half-height bar.

- In a 4-State symbol, "A" represents the ascending bars, "D" the descending bars, "T" the short bars, and "H" the tall bars that both ascend and descend.

A codeword is a symbol, character value, or intermediate level of coding between source data and the graphical encodation.

- A data codeword encodes data according to the rules or scheme of the symbology.

- A check codeword is reserved for error detection and error correction purposes.

Codeword Yield indicates interference between adjacent rows in a 2D barcode. A low Codeword Yield can indicate print conditions where this interference is caused by drag, streaking, or bleeding of ink from one row to another.

Data Safety Margin is the ratio of unused error correction codewords to the recommended number of error correction codewords. A low Data Safety Margin indicates a symbol that is close to reading failure and can be improved by improving printing, correcting the cause of bad or missing symbol characters, or raising the Error Correction Level of the barcode.

Edge Accuracy is a measure of the accuracy of the bars or darkly portioned edge positions within the symbol.

- A low Edge Accuracy indicates print conditions, such as a "print pitch to X-Dimension" mismatch or general edge irregularities (but not uniform print growth), which can lead to hard character decoding.

- The first condition is improved by properly scaling the symbol to the print pitch, and both conditions are improved by making the symbol larger.

The Encoded Message is the alphanumeric and/or control characters used to create a message contained within the barcode and output as part of the decoding process. This information precedes the calculated PQA output and must be manually compared to the characters that should be encoded.

Error Correction is a reader or decoder's use of mathematical processes to reconstruct or replace damaged or missing symbol characters. Error correction characters are specific symbol characters that are created automatically from the other symbol data characters and used for error correction and detection.

- Error Correction Characters are symbol characters that are reserved for error detection and calculated automatically from the other symbol characters.

- Error Correction Level is an indication of the number of characters used in the symbology for error correction. Higher levels of error correction allow for correcting greater potential symbol damage.

- Error Detection is the use of error correction characters to detect whether the presence of errors in the symbol exceeds the error correction capability. Error detection will keep the symbol from being decoded as erroneous data.

Mask Pattern, also known as Masking, is a specific part or characteristic of a QR Code where a process is used to provide a more evenly balanced number of light and dark modules to reduce the occurrence of arrangements of adjoining modules that might interfere with efficient processing of a symbol's image.

Module Errors are individual errors within fixed patterns and data areas. Although often benign, module errors in the fixed regions of a symbol can signal a fault that, in some instances, can prevent proper decoding. They can generally be corrected by using a larger X-dimension and/or cleaning up the print process to remove stray ink, voids, and other inconsistencies in printing.

Print Growth is a measure of the growth or shrinkage of the bar widths, elements, or modules' width and/or height.

- A low print growth grade indicates print conditions that expand or shrink the apparent size of the dark bars or elements, which can cause them to optically disappear.

- In 2d matrix symbols, if the growth or shrinkage in one direction is larger than the other, this can indicate excessive drag in the direction of label travel.

- Potential areas of correction include adjusting the print process, adjusting the original barcode symbol graphic or pattern, or making the symbol larger.

Row Height is an approximate measure of the average height of the elements in a row, which indicates the growth or shrinkage of the element widths. In 2D barcodes, row heights of less than the recommended height can impede barcode readability. This can be corrected by graphically stretching the barcode.

- Useful Row Height is the measured Row Height times the codeword yield. A low Useful Row Height usually indicates print conditions where rows interfere with their adjacent neighboring rows, creating a dead band of wasted scanning in between. Useful row height scales these interfering rows to the printed row height, giving more leeway to symbols printed above the minimum row heights. A poor grade here is corrected either by stretching the symbol vertically or correcting the print condition that causes rows to interfere.

Symbology is a standard means of representing data in a barcode form. Each symbology specification sets out its particular rules of composition or data architecture.

The X-Dimension is an approximate measure of the average width of the narrow elements in a 2D stacked barcode symbol or a single element or module in a 2D matrix symbol, and indicates the growth or shrinkage of the element widths.

Aztec Code PQA Results

The Full Report from a typical scan looks like the following (line numbers have been added in curly brackets):

{1} This is a representative

Aztec Code symbol

{2} >>> PQA from IDAutomation <<<

{3} AZTEC

CODE: 3 layers (Compact) => 23x23 modules

{4} Data Field: 29 data & 22

chks in GF(256), 0 Erasures & 0 Errors

{5} X roughly = 0.021"

{6}

[A] < Core Symbol: 0 errors

{7} [A] < Data Safety Margin = 146%

{8}

[A] < Horizontal Print Growth = +1% of X

{9} [A] < Vertical Print Growth

= +1% of X

{1} is the Encoded Message.

{2} is the Banner heading.

{3} identifies the Symbology (AZTEC CODE) and lists the symbol's size and format.

{4} lists the numbers of Data and Check Words, as well as the Error Correction used.

{5} presents an approximate X-dimension.

{6} lists the number of Module Errors in the central Core Symbol, which consists of the finder bulls-eye, four orientation clusters at its corners, and the mode message along its perimeter. The grade is assigned as:

A if there are 0 (zero) errors,

B if there is 1 error,

1 - 10

C if there are 2 errors,

D if there are 3 errors

F if there are 4 or more errors.

In Screening modes, this parameter is reported as "Too many Code Symbol Errors (3)" when that is the case.

{7} lists the Data Safety Margin. In Aztec Code symbols, the recommended number of error correction words is a minimum that is generally exceeded because any excess codeword capacity is filled with extra check words. Thus, this parameter often exceeds 100%, but it can also be forced to much higher or lower levels by user options.

{8} and {9} list the Horizontal & Vertical Print Growths, respectively. When one direction's growth is substantially larger than the other, excessive bar dragging in the direction of label travel is indicated and should be fixed. When both directions have excessive growth, then either (a) adjustment of the print process or (b) undercutting of the original bar code symbol graphic is recommended.

Data Matrix PQA Results

The Full Report from a typical scan looks like the following (line numbers have been added in curly brackets):

{1} This is a representative Data Matrix symbol

{2}

>>> PQA from IDAutomation <<<

{3} DATA MATRIX ECC200: 24

x 24 modules in size

{4} Data Field: 36 data & 24 chks in

1 block(s) of GF(256)

{5} X roughly = 0.025"

{6} [A] <

Fixed Patterns: 0 module errors

{7} [A] < Data Safety

Margin = 100%

{8} [A] < Horizontal Print Growth = +10% of

X

{9} [A] < Vertical Print Growth = +12% of X

{1} is the Encoded Message.

{2} is the Banner heading.

{3} identifies the Symbology (DATA MATRIX) and lists the symbol's ECC and size.

{4} lists the numbers of Data and Check Words, as well as the error correction used.

{5} presents an approximate X-dimension.

{6} lists the number of Module Errors in the Fixed Patterns, which consist of the Finder "L" and Clocking tracks around the perimeter of the symbol, their adjacent quiet zones, and any interior alignment patterns in larger ECC200 symbols.

In Screening modes, this parameter is reported as "Too many Fixed Pattern Errors (3)" when that is the case.

{7} lists the Data Safety Margin. This parameter is measured and reported only for ECC200 symbols. These symbols have a fixed level of error correction. There is no equivalent parameter for the convolutional error encoding used in older versions of Data Matrix. This parameter is just the "Unused Error Correction" and is always between 0 and 100%.

{8} and {9} list the Horizontal & Vertical Print Growths, respectively.

MaxiCode PQA Results

The Full Report from a typical scan looks like the following (line numbers have been added in curly brackets):

{1} This is a representative Maxicode symbol

{2} >>> PQA from

IDAutomation <<<

{3} MAXICODE: Mode 4

{4} X roughly =

0.043"

{5} [A] < Data Safety Margin = 100%

{6} [A] <

Horizontal Print Growth = +2% of X

{7} [A] < Vertical Print

Growth = -1% of X

{1} is the Encoded Message.

{2} is the Banner heading.

{3} identifies the Symbology (MAXICODE) and lists the symbol's Mode.

{4} presents an approximate X-dimension.

{5} lists the Data Safety Margin. Because the Error Correction level for MaxiCode is fixed for each mode, this parameter is just the "Unused Error Correction," and is always between 0 and 100%.

{6} and {7} list the Horizontal & Vertical Print Growths, respectively.

PDF417 PQA Results

The Full Report from a typical scan looks like the following (line numbers have been added in curly brackets):

{1} This is a representative PDF417 symbol

{2} >>> PQA from

IDAutomation <<<

{3} PDF417: 11 rows x 3 cols, 25 data & 8 chks (ECL = 2)

{4} X roughly = 0.014"

{5} [A] < Row Height = 3.1 X

{6} [A] < Useful Row

Height = 2.5 X (82% Row)

{7} [A] < Data Safety Margin = 100% (0 Erasures &

0Errors)1 - 6

{8} [B] < Edge Accuracy = 59%

{9} [C] < Print Growth = -43%

of X

where:

{1} is always the Encoded Message, the usual data output. In this case, "This is a representative PDF417 symbol".

{2} is a standard Banner heading that marks the start of the PQA portion of the output.

{3} identifies the Symbology, PDF417 (or its derivative COMPOSITE-C), and lists other characteristics of this symbol: the height and width of the data field, the number of data and check characters, and the corresponding Error Correction Level.

{4} presents an approximate X-dimension, presuming normal viewing distance. In the Screening PQA modes, the Symbology Identification from Line {3} is combined with the approximate X-dimension from Line {4}.

{5} lists the average Row Height, assigning the grades as:

A if Row Height >= 2.5 X

F otherwise

In Screening modes, this parameter is reported as "Rows are Too Short (2.2X)" when that is the case.

{6} lists the Useful Row Height, which is the measured Row Height times the codeword yield (listed in parentheses), the percentage of symbol characters scanned that decode. The grade is assigned as:

A if Useful Height >= 2.0 X, else

B if Useful

Height >= 1.6 X, else

C if Useful Height >= 1.3 X, else

D if

Useful Height >= 1.0 X, else

F otherwise

In Screening modes, this parameter is reported as "Useful Row Height is Too Short (1.5X)" when that is the case.

{7} lists the Data Safety Margin, which is the ratio of the unused error correction words to the recommended (!) number of such words. Data Safety Margin can exceed 100% when the ECL is higher than the minimum recommended, or be limited to 50% or lower, even with perfect printing, when the ECL is below the minimum. The grade is assigned as:

A if Safety Margin >= 62%, else

B if Safety

Margin >= 50%, else

C if Safety Margin >= 37%, else

D if

Safety Margin >= 25%, else

F otherwise

In Screening modes, this parameter is reported as "Low Data Safety Margin (44%)" when that is the case.

{8} lists the Edge Accuracy measured in the Start or Stop patterns. The grade is assigned as:

A if Edge Accuracy >= 62%, else

B if Edge

Accuracy >= 50%, else

C if Edge Accuracy >= 37%, else

D if

Edge Accuracy >= 25%, else

F otherwise

In Screening modes, this parameter is reported as "Poor Edge Accuracy (59%)" when that is the case.

{9} lists the Print Growth measured in the Start or Stop patterns (the growth of the dark modules or "bars"). The grade is assigned as:

A if Print Growth is between +/- 20%, else

B if Print Growth

is between +/- 30%, else

C if Print Growth is between +/- 40%,

else

D if Print Growth is between +/- 50%, else

F otherwise

In Screening modes, this parameter is reported as "Excessive Print Growth (33%)" or "Excessive Print Shrinkage (-43%)" when those are the cases. In rare instances where neither a valid Start nor Stop pattern is measurable, yet the symbol is somehow read, lines {8} and {9} are replaced by a message to that effect. The message is either:

"[F] < Start/Stop Decode Fails" in a Full Report or

"Start/Stop Characters are Bad" in a Screening mode.

In Screening modes, it often occurs that none of the parameters are below the Minimum Acceptable grade. In this case, the final PQA line becomes: "All Measurements within range".

QR Code PQA Results

The Full Report from a typical scan looks like the following (line numbers have been added in curly brackets):

{1} This is a representative QR Code symbol

{2} >>> PQA from

IDAutomation <<<

{3} QR CODE: Model 2 Version 3 (29 x

29 modules)

{4} Mask Pattern Reference #3, Error Correction

Level "M"

{5} Data Field: 44 data & 26 checks in 1

block(s) of GF(256)

{6} X roughly = 0.025"

{7} [A] <

Data Safety Margin = 100%

{8} [A] < Horizontal Print Growth =

+20% of X

{9} [A] < Vertical Print Growth = +17% of X

{1} is the Encoded Message.

{2} is the Banner heading.

{3}

identifies the Symbology (QR CODE) and lists the symbol's model,

version, and size.

{4} lists this symbol's Mask Pattern and Error Correction Level.

{5} lists the numbers of

Data and Check Words and their arrangement into blocks.

{6} presents an approximate X-dimension.

{7} lists the Data Safety Margin. "M" is the recommended error correction level for QR Code, so symbols encoded at "H" or "Q" will typically have safety margins exceeding 100%, while those encoded at "L" are limited to values below 50%.

{8} and {9} list the Horizontal & Vertical Print Growths, respectively.

Postnet and Planet Code PQA Results

The Full Report from a typical scan looks like the following (line numbers have been added in curly brackets):

{1} 51591

{2} >>> PQA from IDAutomation <<<

{3} POSTNET: 32

Bars, nominally from 01.30 to 01.56 in. in Width

{4} Bar

Sequence: 10101000011010101010000011101001

{5} [F] (Hi) < Tall

Bar Heights: 0.155 in.

{6} [F] (Hi) < Short Bar Heights: 0.081

in.

{7} [A] (Ok) < Bar Widths = 0.022 in.

{8} [A] (Ok) <

Inter-Bar Gaps = 0.023 in.

{1} is the Encoded Message.

{2} is the Banner heading.

{3} identifies the Symbology (POSTNET or PLANET Code), and lists also the symbol's size and allowed range of measured width.

{4} lists the Bar Sequence, "1" representing a tall bar and "0" representing a short one.

{5} lists the Average Height of the tall bars, specified to fall within 0.115 to 0.125 in. The grades are assigned as:

A if within the middle 67% of the specified tolerances, else 1 -

14

B if within the specified tolerances, else

C if within a

range 25% wider(!) than the specified tolerances, else

D if

within a range 50% wider(!) than the specified tolerances, else

F

otherwise

Note: These forgiving grade assignments, employed throughout the postal symbologies, reflect what are generally tight and unforgiving print specifications.

In Screening modes, this parameter is reported as "Tall" Bars are too Short (or Long) (0.xxx in.)" when that is the case.

{6} lists the Average Height of the short bars, specified to fall within 0.040 to 0.060 in. In Screening modes, this parameter is reported as "Short" Bars are too Short (or Long) (0.xxx in.)" when that is the case.

{7} lists the Average Width of the bars, specified to fall within 0.015 to 0.025 in. In Screening modes, this parameter is reported as "Bars are too Narrow (or Wide) (0.xxx in.)" when that is the case.

{8} lists the Average Space Width between bars, specified to fall within 0.012 to 0.040 in. In Screening modes, this parameter is reported as "Spaces are too Narrow (or Wide) (0.xxx in.)" when that is the case.

4-State Codes PQA Results

The Full Report from a typical scan looks like the following (line numbers have been added in curly brackets):

{1} B15AJ6T

{2} >>> PQA from IDAutomation <<<

{3}

4-STATE(British): 34 Bars, nominally from 38.5 to 42.3 mm. in Width

{4} Bar Sequence: ADHTATDAHDDAADADAADTHTADHHDATHTADH

{5} [A] (Ok)

< "Tall" Bar Extensions: 2.79 mm. from center

{6} [F] (Hi) <

"Short" Bar Extensions: 1.00 mm. from center

{7} [B] (Hi) < Bar

Widths = 0.60 mm.

{8} [A] (Ok) < Inter-Bar Gaps = 0.59 mm.

{1} is the Encoded Message.

{2} is the Banner heading.

{3} identifies the Symbology, 4-STATE (British, or KIX, Canadian, Japanese, or Australian), and also lists this symbol's size and allowed range of measured width.

{4} lists the Bar Sequence, "A" representing Ascending bars, "D" representing Descending bars, "T" representing Tracker (short) bars, and "H" representing tall bars that both ascend and descend.

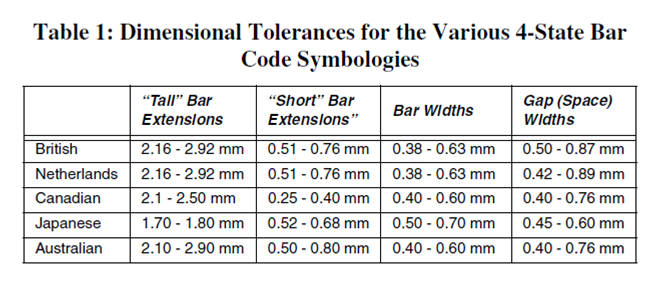

{5} lists the Average Extension from the centerline of the tall ascenders and descenders, as specified in the table below. In Screening modes, this parameter is reported as "Tall" Bar Extensions are too Short (or Long) (0.xxx in.)" when that is the case.

6} lists the Average Extensions from the centerline of the Short tracks, as specified in Table 1.

In Screening modes, this parameter is reported as "Short" Bar Extensions are too Short (or

Long) (0.xxx in.)" when that is the case.

{7} lists the Average Width of the bars, as specified in the table below.

{8} lists the Average Space Width between bars, as specified in the table below.

Note: For the Canadian and Australian 4-State

symbologies only, any bar error that has invoked their error

correction triggers an additional PQA parameter line:

"[F] < One or more Bars are in Error!" in a Full Report or

"One or more Bars are in Error!" in Screening mode.